From start to finish, our team will work with you side by side and make sure you receive great service and the best possible outcome for your project.

The process is very straightforward, and we follow a structure as detailed below.

Planning

An urbanpod™ shouldn’t require planning consent as they normally fall under permitted development, however due to your location or restrictions you may require consent, we will guide you along the way. We have 100% success rate in achieving planning permission where required for our pods. Our skilled architects and design team specialise in modular pod construction and design, so all our products meet current new-build standards – which makes for a smoother planning and warrant process.

We can guide you seamlessly from the start of your project through this process, or we can work with your existing architectural plans – whatever you prefer.

As a guide, it typically takes 8-12 weeks to gain the appropriate permissions before construction can commence.

Design

urbanpods™ offers a personalised design experience tailored to your specifications, whether it involves adding enhancements to a standard pod or creating a completely bespoke design to align with your needs and budget.

The process commences with an initial on-site visit to evaluate any necessary ground preparation and assess the suitability of the site for your requirements. Collaborating closely with you, we develop the design, and our comprehensive quotation service ensures that all considerations are accounted for………. there are no hidden costs with our products!!

To provide a visual representation, we supply a 3D rendering of your pod within its designated space, allowing you to see the precise placement of windows and doors in relation to the available space and the features outlined in your initial brief or architectural project drawing. Upon your approval of the designs and, if required, the need for permissions, we seamlessly coordinate with our architect or yours to initiate the approval process and pave the way for manufacturing and construction.

Construction

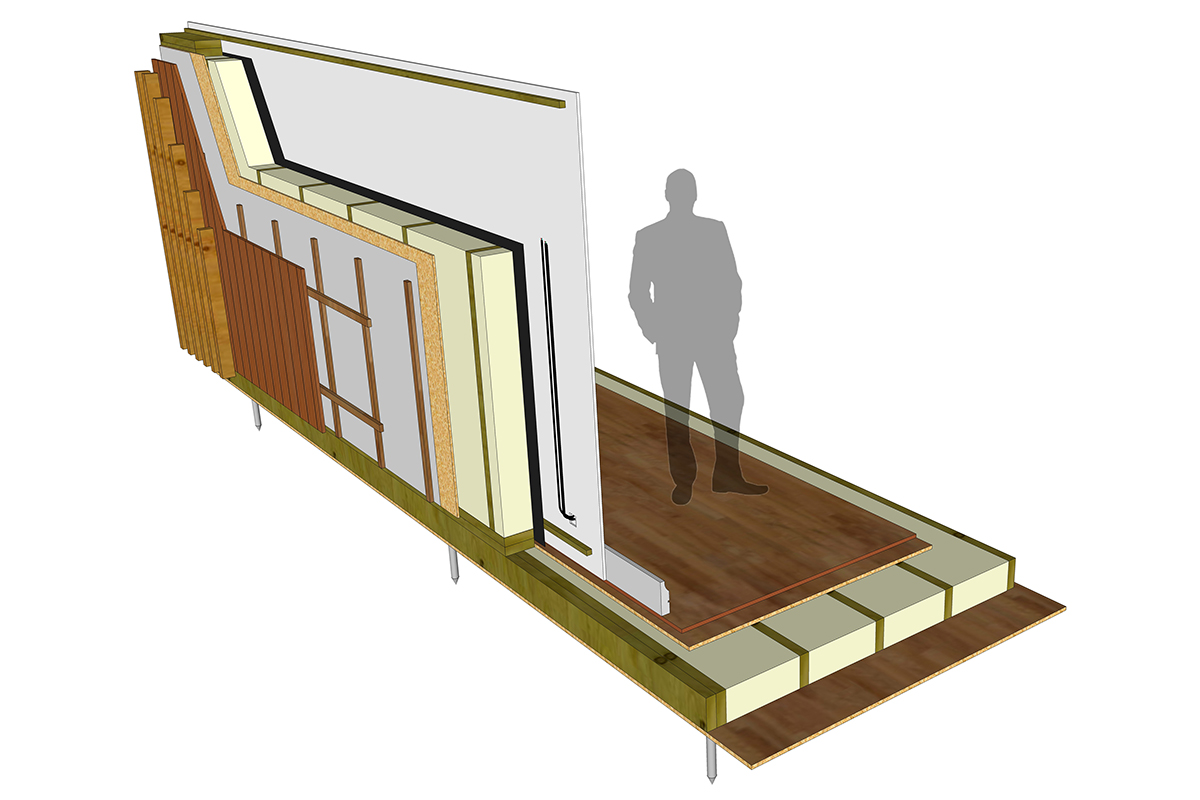

The construction process at your home is normally carried out within 10 working days… sometimes even quicker!

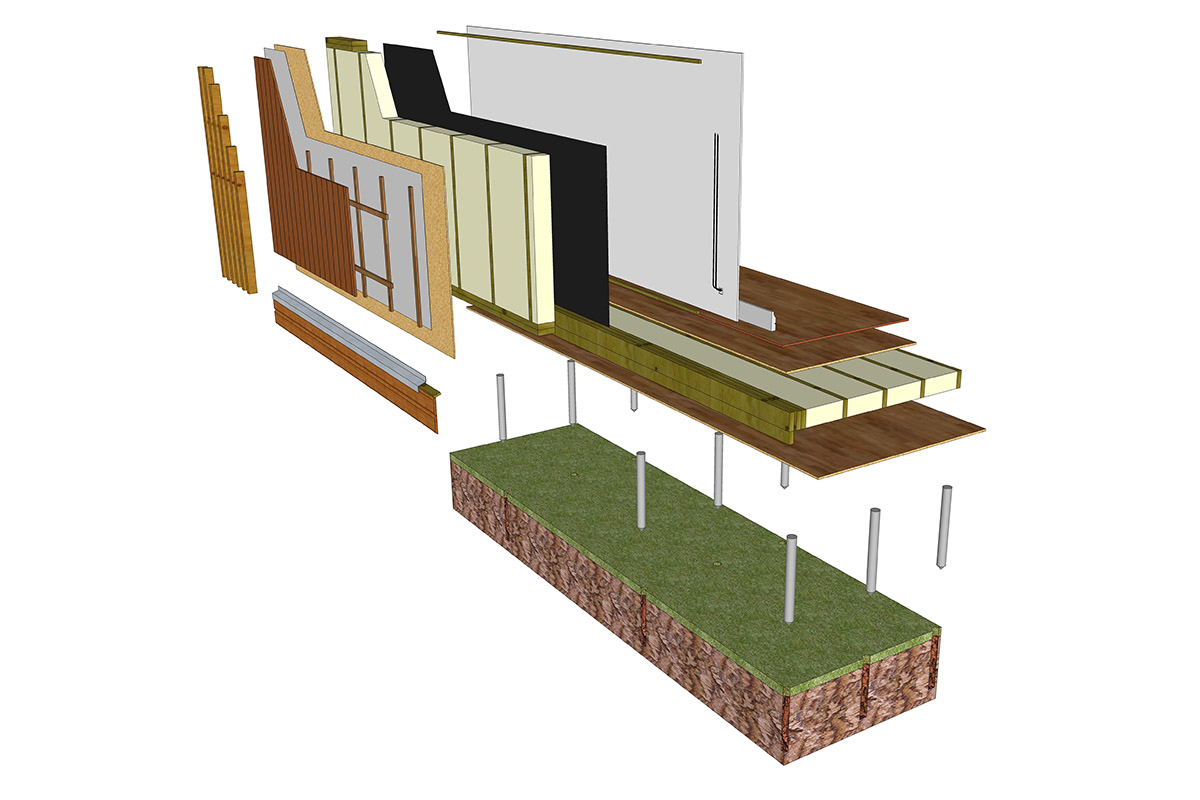

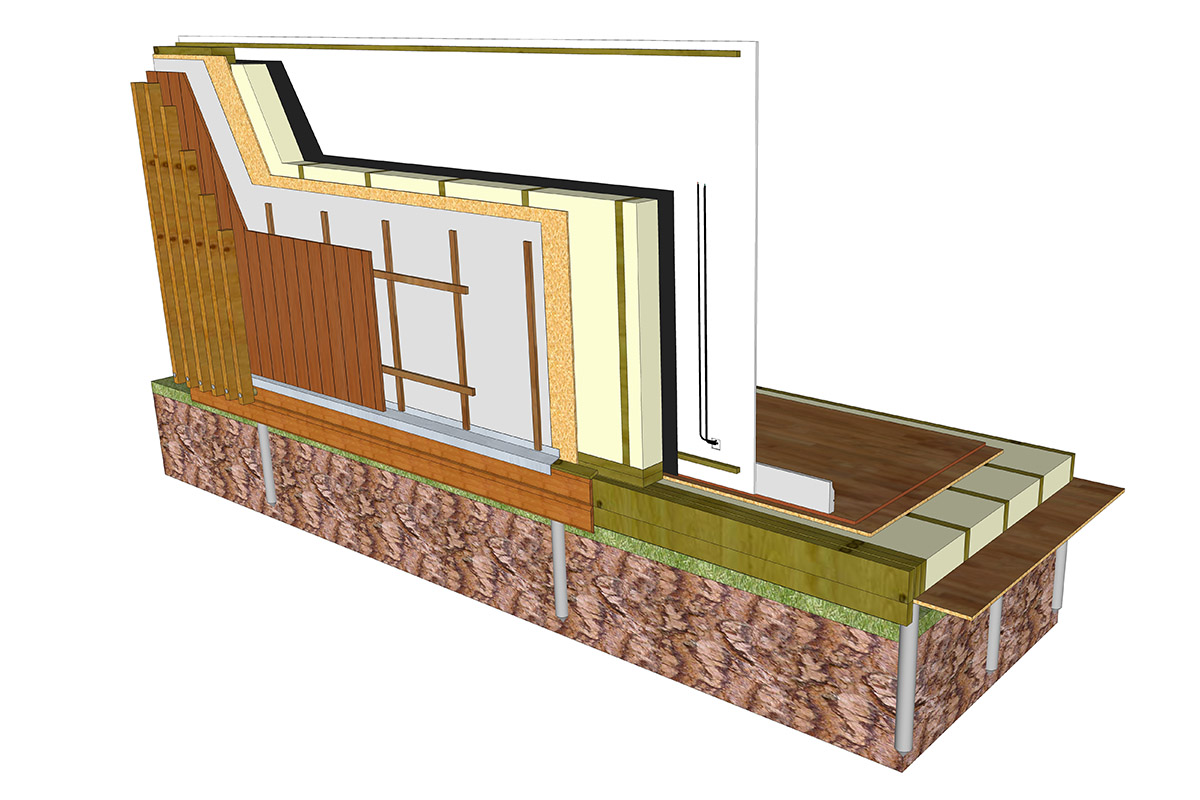

Our products are constructed at our facility in Livingston using the finest materials and modern, efficient and eco-friendly build techniques. We use a ground screw foundation system, so no concrete is required and very little ground preparation as a result. Our pods are so thermally and energy efficient – they have virtually no heat loss. We use sustainable wood cladding and materials and as an added commitment…. urbanpods is committed to planting one tree for every pod created.

Your urbanpod can sometimes be fully constructed at our facility and lifted by crane into position; or they can be partially constructed and brought to your site in sections ready for final assembly by our team. The chosen method is dependent on the size of the pod and access to the site.

Result

The best result for us is to have happy clients. Happy clients have a fantastic new space to enhance their organisations, big or small. And to date, we have many happy clients, delighted with the results and enjoying their new pods.

“We got our Massimo installed this week, team urbanpods were amazing went like clockwork our garden bar looks amazing finishing touches by us tomorrow, Ross we can’t thank you and your team enough would highly recommend”

– Alix Scott

Construction cut-through

Our materials

We use the most innovative and up to date building materials and techniques on the market today. This ensures our pods are not only stunning, but they perform thermally, acoustically and to the same standards you’d expect from a new build house. Our processes involve rigorous testing to ensure our pods suffer no heat loss and result in a product that is super cosy any time of the year. Our attention to detail means our pods are of the highest quality you can buy and will stand the test of time.

OUR PODS

Our urbanpods™ are pre-manufactured either fully constructed or in parts and shipped out to our clients’ homes for swift construction on site thus minimising time spent at your home, we endeavor at all times to keep the process as simple as it can be from conception to completion, it’s what separates us from our competitors.